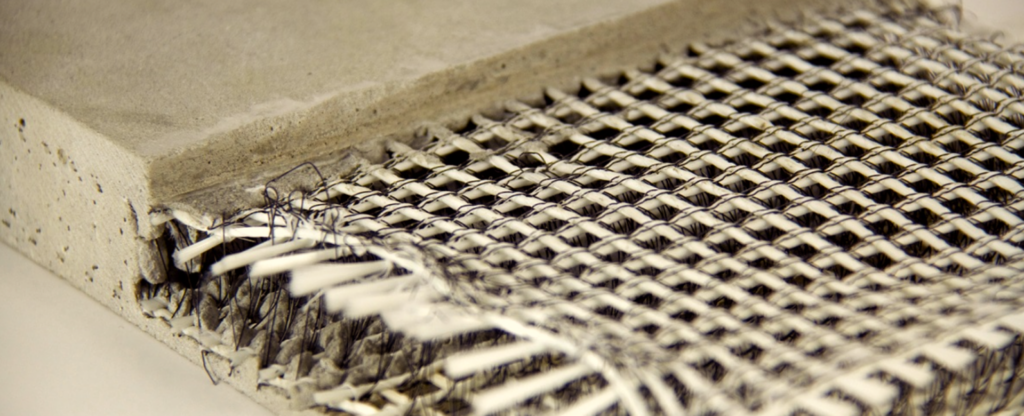

Textiles are used to create waterproof and insulation membranes that can be applied to roofs, walls, and foundations to protect buildings from water infiltration and heat loss. Industrial textiles are used in construction industry to provide waterproofing and insulation for various types of buildings and structures. They offer several benefits over traditional materials, such as ease of installation, flexibility and durability. Waterproofing textiles are used to protect buildings and structures from water infiltration, by applying a protective layer on the surface of a structure. These textiles are often made from synthetic fibers, such as polypropylene or polyester, and can be reinforced with additional layers of material for added strength. They can be applied as a coating, membrane or in a liquid form. Insulation textiles are used to reduce heat loss and gain in buildings and structures by providing a barrier to heat flow. They are often made from fibers such as glass, mineral wool, or polyester and can be applied in the form of batts, blankets, loose fill or spray-on. They are used in walls, roofs, and floors to help keep buildings warm in the winter and cool in the summer. Overall, industrial textiles offer a cost-effective and efficient solution for waterproofing and insulation in construction industry, providing energy efficiency and protection to the buildings and structures from various weather conditions.